Casing&Tubing Production Line

The company currently has 4 oil casing production lines, of which 33.4-177.8mm2, 177.8-340mm1, 406-762mm1, can process and supply OD 33.4~762mm, J55, K55, L80, N80-1/Q, P110 , C90, C110, Q125 and other steel grades, oil well pipes, casings, couplings and short connections of various thread types, with an annual processing capacity of 120,000 tons.It can produce oil casing with a diameter of 33.4mm-762mm,processing diameter 33-762mm.Sand control pipes and screens: laser-slotted oil casing, wound wire oil casing, couplings, drill pipes, wire-wound screens, punched screens, slotted screens, and drilling screens.

Hydraulic upsetting press

Hydraulic upsetting press chosen for this production has enough capacity to upset the minimum and maximum tubings from2 3/8 to4 1/2 (from 60.3 mm to 114.3 mm ).

2 sets of hydraulic upsetting presses are placed simultaneously, one set of hydraulic upsetting press is used to finish upsetting to one end of tubing, another set of hydraulic upsetting press used upset another end of tubing, which greatly increase the productivity and efficiency.

Drift mandrel testing machine

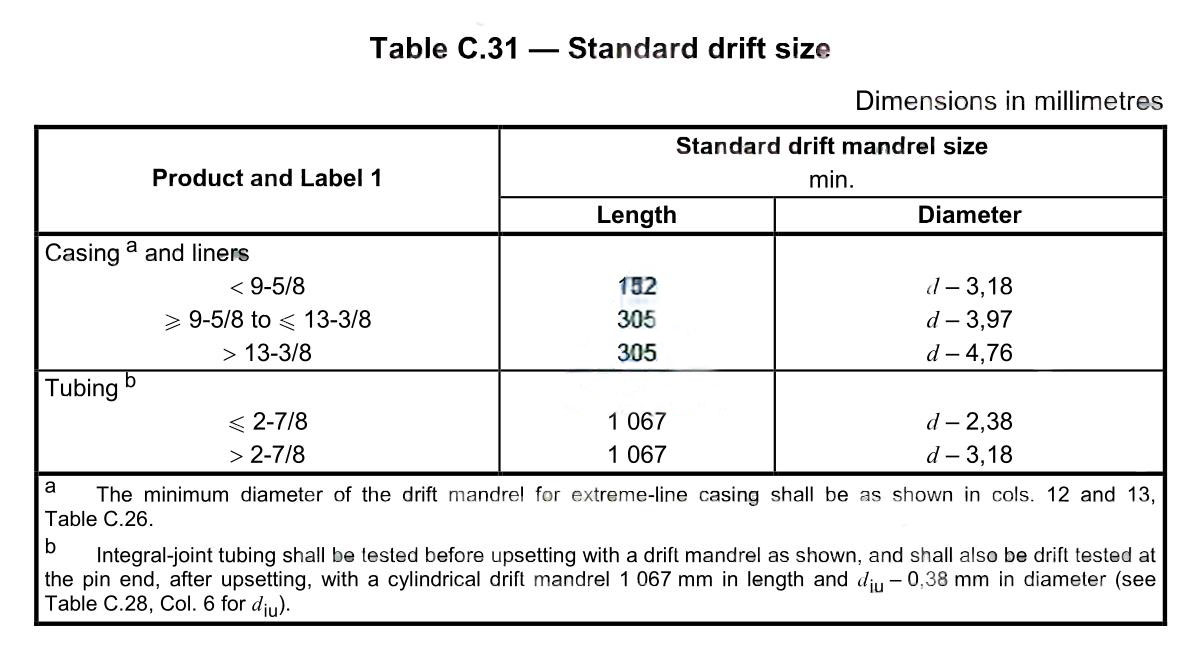

After upsetting, drift mandrel testing should be done according to API 5CT standard.

This drift mandrel testing machine is a special equipment for oil pipe diameter quality

inspection. It adopts standard diameter gauge to test the cylindricity and straightness of

the oil pipe. The oil tubing drifting mandrel testing machine meets the requirement of Table

C.31- Standard drift size in API SPEC 5CT standard.

Oil country lathe

Eonomy type flat bed CNC oil country lathe, moderate slant bed CNC oil country lathe and high performance CNC oil country lathe.Economy type flat bed CNC oil country lathe is equipped with double pneumatic chucks, V4 electric turret, SINUMERIK808D or Fanuc 0i-TF CNC system.Moderate slant bed CNC oil country lathe is equipped with double hydraulic chucks, H8 hydraulic turret, Fanuc 0i-TF CNC system. The productivity is 4-5 times of ordinary oil country lathe.All of 3 types of oil country lathe can meet the precision requirement of API 5B standard.

Hydrostatic testing machine

The tubing hydrostatic testing machine adopts advanced radial sealing method, which requires end face sealing without thread connection, and adopts a wedge bearing device.The human-machine interface and the computer real-time monitoring system can display the pressure curve and value in real time, and cumulatively record and save each parameter.

EN

EN FR

FR ES

ES PT

PT AR

AR DE

DE