Drill Pipe Production Line

API 5DP drill pipe production line is composed by induction heating furnace, automatic feeding and discharging device, hydraulic upsetting press, drift mandrel testing machine, drill pipe heat treatment line, hydraulic straightening machine, oil country lathe, friction welding machine, welding area heat treatment line, painting machine, length & and weight measuring machine and color coding & marking machine, etc.

Hydraulic drill pipe upsetting machine

The rigidity of the main machine is increased, the upsetting force of 400T, and the cavity of 256mm make its working range far beyond that of other models; due to the use of a bilateral locking mechanism, it balances the tilting force of the placenta and makes its work more stable

Hydraulic friction welding machine

The hydraulic friction welding machine can realize automatic tube body feeding, friction welding, inside and outside welding bead removing, drill pipe discharge after welding. The inner welding bead removal is realized by internal punch, outer welding bead removal is done by cutting tool. The equipment actions are consistent, accurate, and the welding part of workpiece is welded at full contact surface, axial and radial orientation is accurate.

Welding area heat treatment line

Intermediate frequency induction furnace is used to heat the welding area of drill pipe to annealing temperature to remove welding stress. After that, welding area is heated to quenching temperature, then water is sprayed to welding area for cooling. At last, welding area is heated to tempering temperature and kept in this temperature for some time.The induction coils have functions of position adjustment(up and down, left and right, front and back) to ensure accurate heating position.During the heating process, drill pipe is rotated on the pipe conveyor to ensure uniform temperature.

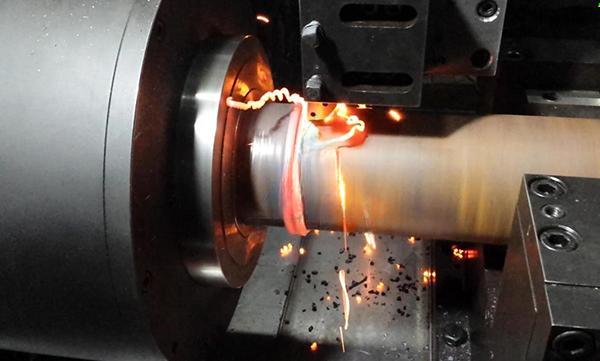

Pipe Threading Lathe

CNC pipe thread lathe is a new type of CNC machine tool specially designed and manufactured for the thread processing requirements of oil pipelines, drill pipes and casings in petroleum, chemical and metallurgical industries. The machine tool adopts double chuck clamping workpiece, three-speed inverter and CNC system automatic control. It can accurately process various internal and external threads and has the function of ordinary CNC lathe.

EN

EN FR

FR ES

ES PT

PT AR

AR DE

DE