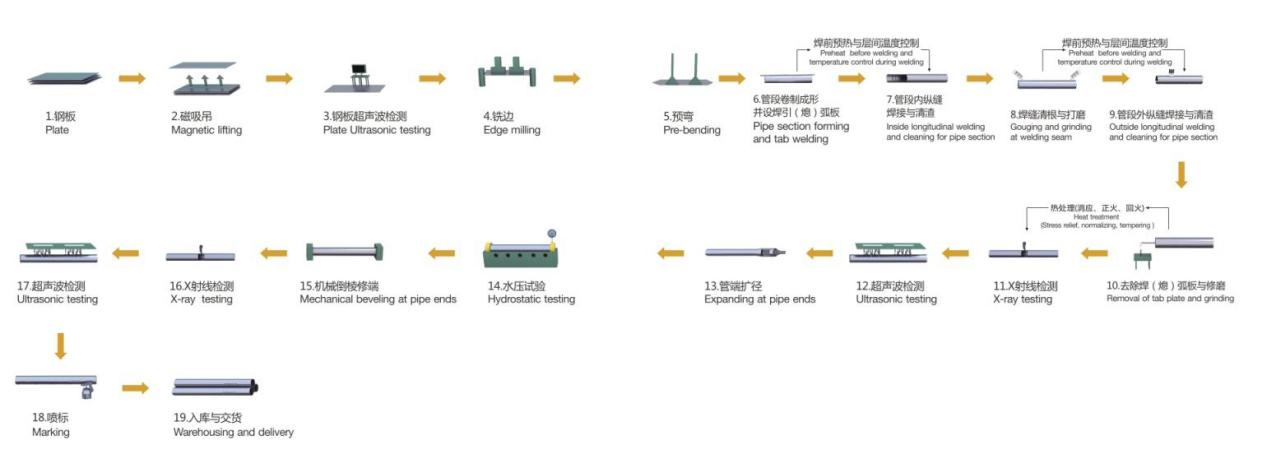

HME Roll Forming Production Line

The production line is formed by "CCO" using the mandrel rolling method, and is formed by the cold expansion process after welding, and is formed by a three-roll/four-roll bending machine. It can produce straight seam welded pipes with an outer diameter of Φ324mm-Φ7000mm , wall thickness of 8mm-200mm, and a length of 3m-7m. Pre-heat treatment, and then use single wire and multi-wire for inner direct welding, outer direct welding, inner girth welding, and outer girth welding. The feature of this production line is that the product has a large wall thickness and large diameter, which can be widely used in structural pipes, such as steel structure bridges, offshore platform equipment, super-long pipe piles, etc.

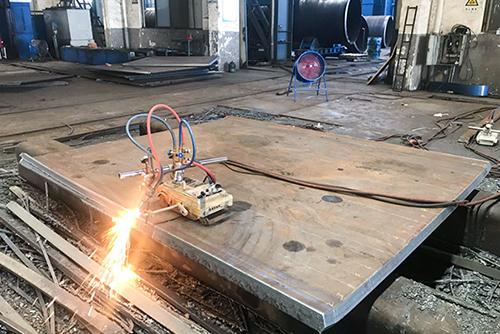

Super thickness plate cutting equipment 2000 tons Pre-bend Machine

Three rolls plate bender Machine Forming Machine

Straight Welding Equipment Splice Welding Equipment

EN

EN FR

FR ES

ES PT

PT AR

AR DE

DE