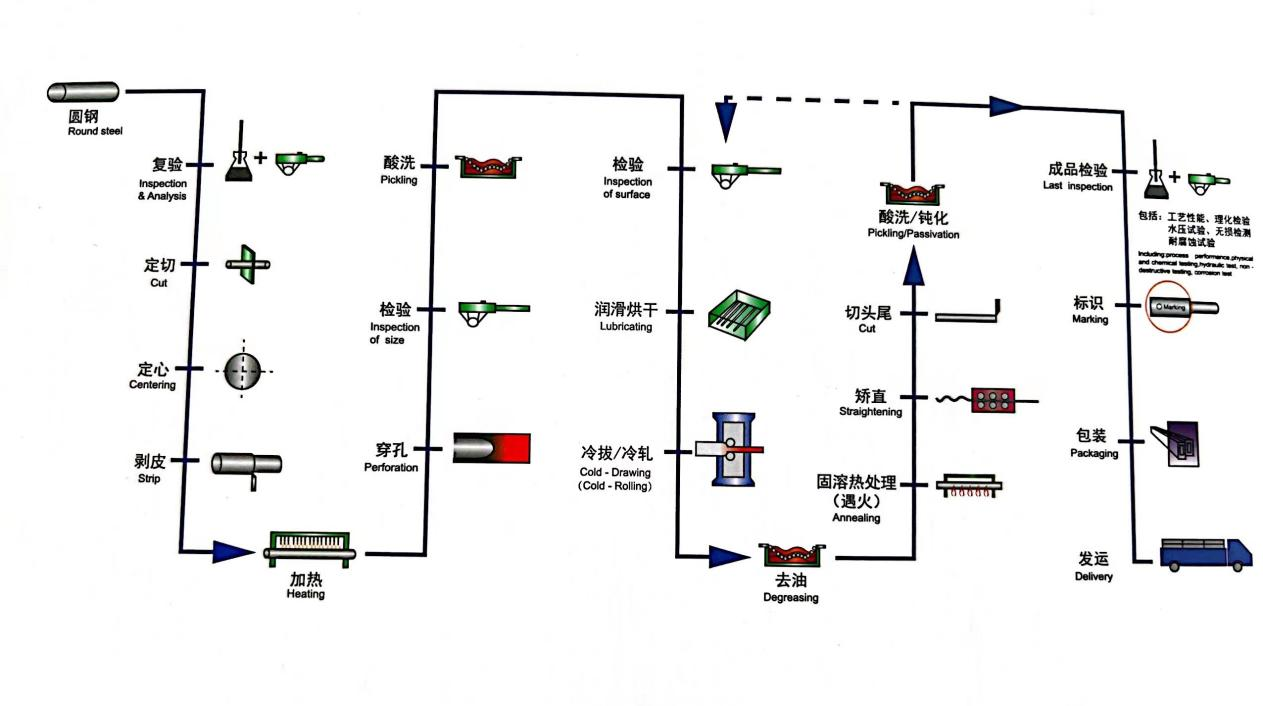

Stainless Seamless Steel Pipe Production Line

The company has production equipment: 32 cold drawing machines, 9 LG60 cold rolling mills, 2 LG120 cold rolling mills, and 1 LG280 cold rolling mill. The inspection equipment includes chemical composition analyzer, universal chemical testing machine, eddy current flaw detector, ultrasonic flaw detector, hydraulic testing machine, spectrometer imported from Germany and other testing equipment. The production specifications are: outer diameter Φ6~Φ762mm, wall thickness 0.5~50mm; main The grades are: 304L/H, 316L/H, 321L/H, 317L, 310S, 201B, 201H, 2205, S31803, S32750, TP309, TP347/347H, 904L, etc.; GOST, JIS, etc., are widely used in petrochemical, fertilizer, nuclear power, boiler, ship, environmental protection, aviation, paper, food and medical fields. The company is dominated by TP304, 304, TP304L, TP316, TP316L, TP321, 321 stainless steel seamless pipes, especially 310S, 220S, S318003, S32205, S3275, S32760 high temperature resistant steel pipes.

Cold Drawing Machine Pickling Rolling Mill

Straightening Machine Polish Machine

Stainless Seamless Steel Pipe Production Process

EN

EN FR

FR ES

ES PT

PT AR

AR DE

DE