Stainless Welded Steel Pipe Production Line

The introduction of international advanced new stainless steel welded pipe production line, Φ630 automatic continuous production line unit and multiple sets of single-sided welding and double-sided forming German plasma welding and submerged arc welding units, the production of welded pipes can be divided into single straight seam, double straight seam and ring Seam butt joint: single seam (φ6mm-φ1422mm), wall thickness from 0.2mm to 40mm; double seam (φ630-φ2020) wall thickness from 2mm to 80mm, annular seam (above Φ630), wall thickness from 2mm to 100mm. At present, the main materials used by the company are: nickel-based stainless steel (NO8904, N06600, N08825, etc.), duplex stainless steel (S32750, S31803, S32205), austenitic stainless steel (310S, 309S, 316L, 321, 304L, 304, etc.), iron Element body (430, 409L, etc.), copper-nickel alloy (C70600, C70620) and some special steel grades (254SMO, S30815, 253MA)

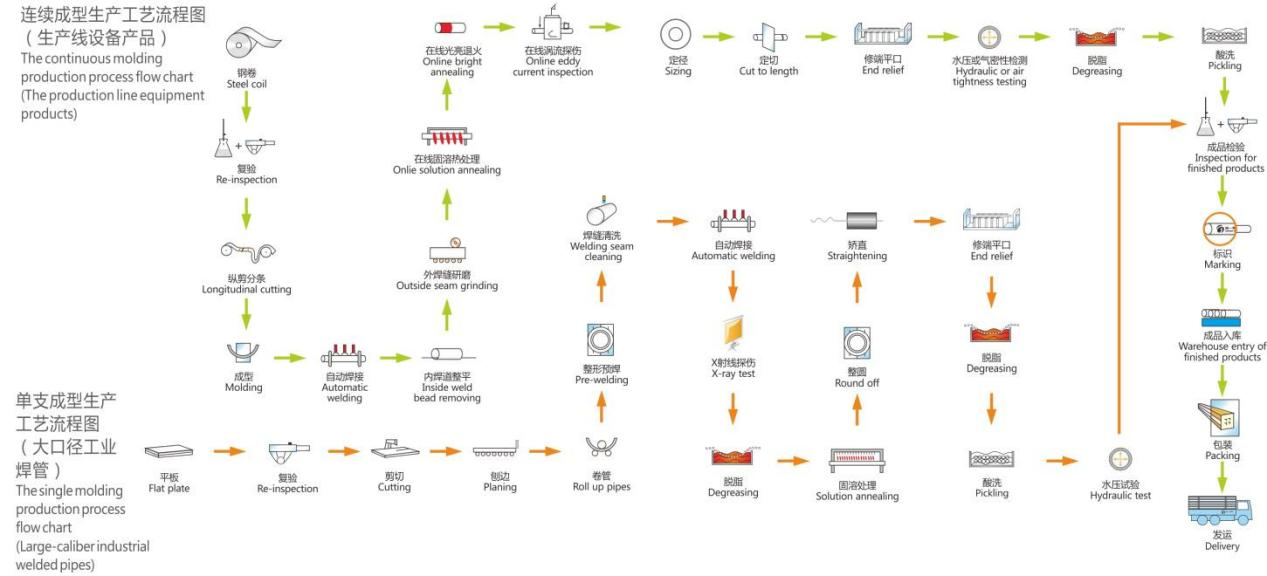

Single Forming Process Production Line

It has the internationally advanced JCO large-diameter single forming production line, 3200-ton CNC bending forming unit, and rolling unit. It has stainless steel bright, solution heat treatment equipment, online solid solution of pipes, eddy current flaw detection and ultrasonic cleaning equipment, and has perfect inspection and testing. The equipment covers various physical, chemical and non-destructive testing items from raw materials, production processes and finished products. Production and inspection are carried out in strict accordance with ASTM American Standard, JIS Japanese Standard, DIN German Standard and industry standards. The company's products have complete specifications, advanced technology and high quality. The production of pipes covers 304, 304L, 316L, 321, 347, 310S, dual-phase steel, nickel-based alloy steel and other stainless steel materials. Stainless steel pipes of different grades with wall thickness from 0.2mm to 40mm

|

Large Pipe Welding |

Internal Welding Edg Beam Welding Machine |

Heat Treatment |

|

|

|

|

Pickling passivation |

Cantilever Welding Machine |

Bending Machine |

|

|

|

Continuous Molding Process Production Line

There are more than 20 continuous molding production lines with complete product specifications, which can produce outer diameters from 6mm to 406mm, wall thicknesses from 0.4mm to 20mm, and an annual design capacity of more than 40,000 tons.

130 Model Unit Production Line (Max OD 426mm) Forming Machine Pipe Welding Machine

On-line Solution Heat Treatment Shaping Machine Automatic Welding

Stainless Welded Steel Pipe Production Process

EN

EN FR

FR ES

ES PT

PT AR

AR DE

DE