Description

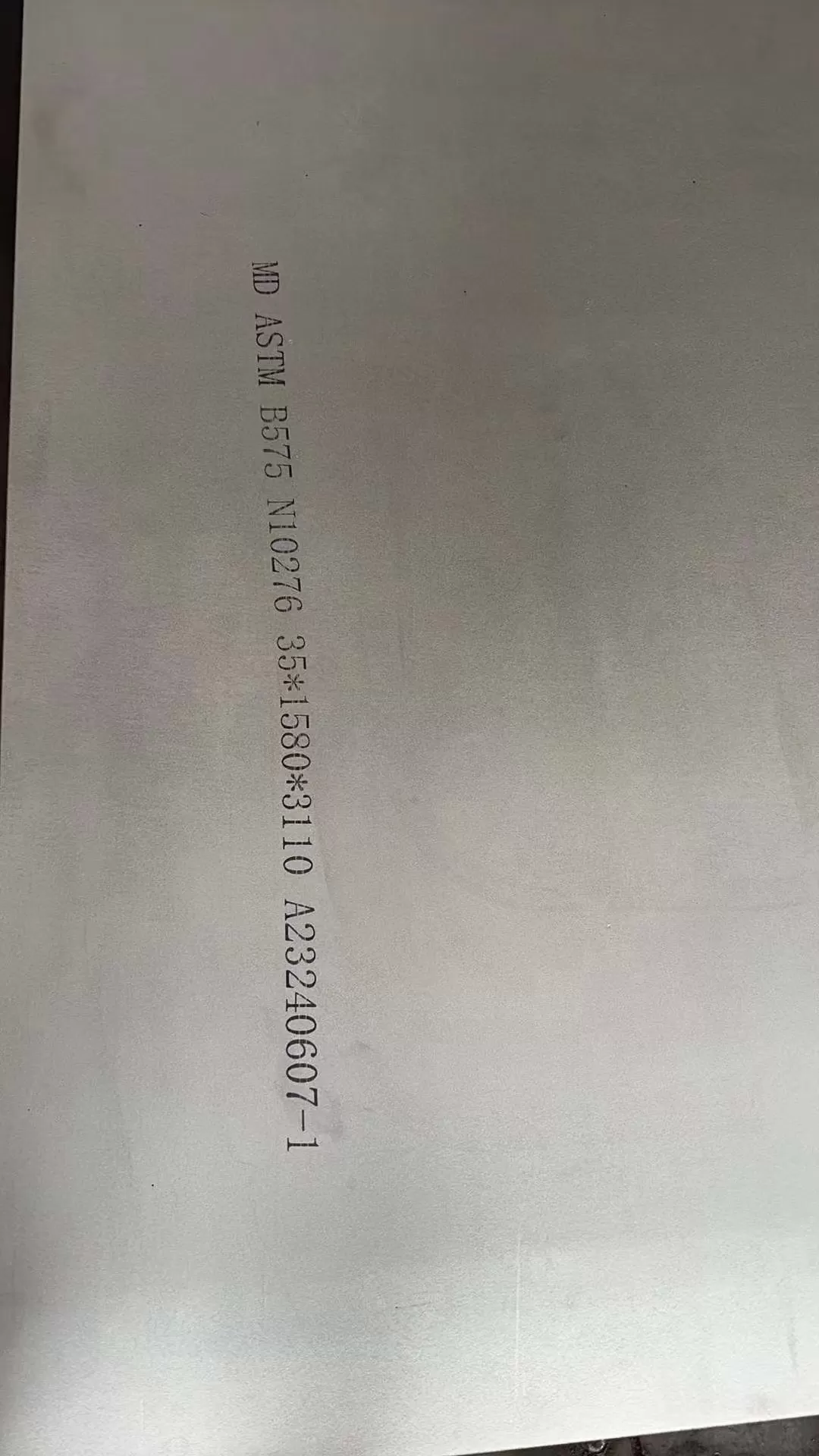

Hastelloy C276

Material

UNS N10276, Alloy C-276, W.Nr. 2.4819, Hastelloy® C-276

Note that the designation “ Hastelloy®” is registered trademarks of Haynes International Inc.

Overview

UNS N10276 is a solid solution strengthened nickel-molybdenum-chromium alloy with a small amount of tungsten, which exhibits excellent corrosion resistance in an assortment of harsh environments. The high molybdenum content imparts resistance to localized corrosion such as pitting. The low carbon minimizes carbide precipitation during welding to maintain resistance to intergranular attack in heat-affected zones of welded joints. In addition, Hastelloy C-276 is also ductile, easily formed and welded.

Application

- Chemical Processing: Pipes, valves, pumps, heat exchangers, and vessels where resistance to corrosive chemicals is crucial

- Oil and Gas: Valves, piping systems, pump shafts, and downhole equipment

- Desalination Plants: Evaporators, heat exchangers, and piping systems

- Pollution Control: Scrubbers, flue gas desulfurization systems, and exhaust ducts

- Pharmaceutical Industry: Reactors, storage vessels, and equipment that handle corrosive chemicals and pharmaceutical intermediates

- Aerospace: Aircraft exhaust systems, gas turbine components, and missile and rocket motors

- Waste Treatment: Tanks, scrubbers, and pumpsries

Chemical Composition (%)

| Material | Ni | Mo | Cr | Fe | W | Co | Mn | C |

|---|---|---|---|---|---|---|---|---|

| N10276 | Balance | 15.0-17.0 | 14.5-16.5 | 4.00-7.00 | 3.00-4.50 | 2.50 max | 1.00 max | 0.01 max |

Mechanical Property

| Material | Tensile strength | Yield strength 0,2 | Elongation | Hardness HB30 |

|---|---|---|---|---|

| N10276 | 530-730 N/mm² | 210 N/mm² | 30% | 230HB |

Corrosion Resistance

Hastelloy C-276 is known as the most universally corrosion resistant material available today, and resistant to general corrosion, stress corrosion cracking, pitting and crevice corrosion in a broad range of severe environments. Its resistance to carbide precipitation during welding maintains corrosion resistance in the heat-affected zones of welded joints. Not only Hastelloy C-276 has exceptional resistance to sulfuric acid and hydrochloric acid, acid chlorides, solvents, formic and acetic acids, acetic anhydride, wet chloride gas, hypochlorites and chlorine solutions, but also it has excellent resistance to phosphoric acid at all temperatures below the boiling point and at concentrations lower than 65 wt%. In addition, Alloy C-276 exhibits excellent resistance to corrosion by seawater especially under crevice conditions which induce attack in other commonly used materials.

Heat Treatment

Heat treatment of Hastelloy C-276 is commonly performed to enhance its mechanical properties, reduce residual stresses, and optimize its corrosion resistance. Stress relieving, solution annealing, and aging are some common heat treatment processes. The desired outcomes and the specific application requirement of Alloy C-276 vary, the specific heat treatment process may vary.

Heating and Pickling

Heating is commonly performed processes in the treatment of Hastelloy C-276 to achieve a specific temperature range for subsequent processes like welding, hot forming, or stress relieving, improve material ductility, reduce residual stresses, and facilitate further fabrication. Alloy C-276 generally uses esistance heating, induction heating, or furnace heating to achieve the desired temperature, ensure that the heating is uniform to prevent thermal gradients and potential distortion.

Pickling is a chemical process, typically performed after welding, hot forming, or when the material's surface has become contaminated, to remove surface contaminants, scale, and oxide layers from Hastelloy C-276. Pickling involves immersing the material in an acid solution to dissolve the unwanted layers. Commonly used acids include a mixture of nitric and hydrofluoric acids or a mixture of nitric and hydrochloric acids. As for immersion time, it depends on the severity of surface contaminants and the desired level of cleaning.

Hot and Cold Forming

The hot forming of Hastelloy C-276 should be between 1600 and 2250°F (870 and 1230°C), with all heavy forming above 2000°F (1090°C). The alloy is normally annealed at 2100-2150°F (1150-1175°C) and rapidly cooled such as by water quenching.

Hastelloy C-276 is also suitable for cold forming processes, the cold working process include techniques such as bending, drawing, deep drawing, or cold rolling etc,. The alloy exhibits high work hardening rates, meaning it becomes harder and more difficult to deform as it is cold worked. Frequent annealing or intermediate heat treatments may be necessary to restore ductility and reduce the risk of cracking.

Machining

Hastelloy C-276 is a group of nickel-based superalloys known for their excellent corrosion resistance, high-temperature strength, and good fabricability. Machining Hastelloy alloys can be challenging due to their toughness and work-hardening tendencies, but with proper techniques, it is possible to achieve good results.

Welding

Hastelloy C-276 has good weldability and can be used as-welded for most applications. INCOWELD® filler metal and welding electrode 686CPT® can be used to “overmatch” Alloy C-276 where enhanced corrosion resistance is required.

Product Forms

- Bar & Rod

- Plate & Sheet

- Coil & Strip

- Pipe & Tube

- Fitting: Flange, Tee, Elbow, Reducer etc.

- Forging: Ring, Shaft, Circle, Block etc.

Note

Yupeng is a supplier with more than 15 years of experience in the special metal field, we always adheres to the business phiosophy of "customer-centered", tries its best to meet the requirements of customers and pursues win-win cooperation with customers. Are you looking for special metal products one-stop supplier! Contact Us Now! Email: admin@yupsteel.com

EN

EN FR

FR ES

ES PT

PT AR

AR DE

DE