316l stainless steel tube suppliers

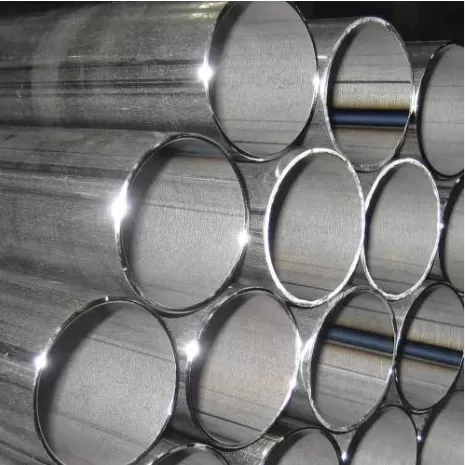

A Stainless steel tube is a cylindrical hollow product made from corrosion-resistant alloy, primarily composed of iron, chromium, nickel, and other elements. It is renowned for its durability and resistance to rust and corrosion, making it ideal for a wide range of applications in industries such as construction, automotive, and manufacturing. Stainless steel tubes come in various shapes and sizes, including round, square, and rectangular profiles, tailored to suit specific engineering and structural needs.

Yupeng Steel, a leading manufacturer in the field, ensures that Stainless steel tubes exhibit exceptional strength and longevity due to their high chromium content, which forms a protective oxide layer on the surface. This layer enhances resistance to oxidation and corrosion, even in harsh environments. The composition typically includes chromium (for corrosion resistance), nickel (for ductility and toughness), and sometimes molybdenum (for enhanced resistance in acidic conditions). These properties make Stainless steel tubes indispensable for applications demanding reliability and longevity in diverse industrial settings.

Yupeng 316l stainless steel tube suppliers

A Stainless steel tube is a cylindrical conduit made from durable and corrosion-resistant Stainless steel, designed for various industrial and commercial applications. It is fabricated through welding or seamless processes, ensuring robustness and longevity in challenging environments where corrosion resistance is paramount.

The benefits of Stainless steel tubes include exceptional durability, high strength-to-weight ratio, and resistance to corrosion, making them ideal for applications in construction, automotive, and manufacturing sectors. They offer versatility in fluid and gas transport, structural support in architectural projects, and reliability in heat exchangers and mechanical systems. Yupeng Steel excels in producing top-quality Stainless steel tubes, adhering to rigorous manufacturing standards to deliver products that meet the stringent demands of global industries.

FAQ

Q: How are Stainless steel tubes manufactured?

A: Manufacturing methods include seamless hot rolling or cold drawing for seamless tubes, and welding (such as TIG or laser welding) for welded tubes.

Q: What are the applications of seamless Stainless steel tubes?

A: Applications include high-pressure gas and fluid transmission, heat exchangers, automotive components, and precision instrumentation.

Q: How are Stainless steel tubes used in construction?

A: They are used for structural supports, handrails, architectural features, and facades due to their strength, aesthetic appeal, and resistance to corrosion.

Q: What are the applications of welded Stainless steel tubes?

A: Applications include plumbing, HVAC systems, process piping in chemical plants, and automotive exhaust systems.

Reviews

Atticus

The stainless steel plates from this supplier are exceptional in quality. They are incredibly durable and resistant to corrosion, making them perfect for our industrial applications. Highly recommended!

Dashiell

I have used many different types of stainless steel plates, but these are by far the best. The material is top-notch, and they arrived in perfect condition. Will definitely buy again!

Latest Inquiries

To protect the privacy of our buyers, only public service email domains like Gmail, Yahoo, and MSN will be displayed. Additionally, only a limited portion of the inquiry content will be shown.

Ella****@gmail.comCanada

Our company requires a reliable source of stainless steel plates and rolls for industrial applicatio...

Henry***@vitamaxprime.comAustria

I am looking for stainless steel plates and rolls with specific dimensions and grades for a large-sc...

Related product categories

- 316 stainless steel tube manufacturer

- stainless steel round tube price

- 321 stainless steel tube manufacturers

- 22mm 316 stainless steel tube

- 35mm stainless steel tube manufacturers

- 25mm 316 stainless steel tube

- 420 stainless steel tube manufacturers

- 316 seamless stainless steel tube

- 904l stainless steel tube manufacturers

- 316 stainless steel square tube

- china 321 stainless steel tube manufacturers

- 316 stainless steel tube for sale

EN

EN FR

FR ES

ES PT

PT AR

AR DE

DE