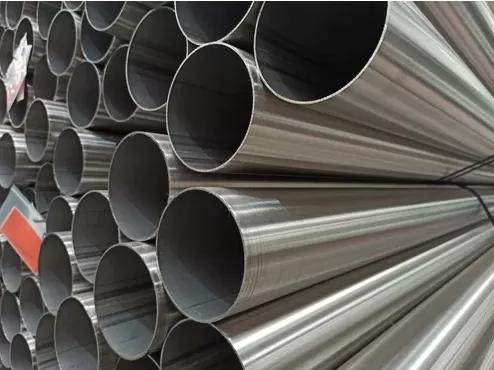

304 stainless steel tube manufacturers

A Stainless steel tube is a robust, corrosion-resistant cylindrical structure manufactured from durable Stainless steel. It is fabricated through seamless or welded processes, ensuring integrity in harsh environments where corrosion and heat resistance are critical.

Stainless steel tubes find extensive applications across various industries, including construction, automotive, and manufacturing. They serve as reliable conduits for fluid and gas transport, structural components in architectural projects, and essential parts in heat exchangers and mechanical systems. Composed primarily of iron, chromium, nickel, and alloying elements like molybdenum, Stainless steel tubes offer high tensile strength, exceptional corrosion resistance, and thermal stability. Yupeng Steel excels in producing high-quality Stainless steel tubes, meeting global standards and catering to diverse industrial needs with precision-engineered solutions.

Yupeng 304 stainless steel tube manufacturers

A Stainless steel tube is a cylindrical conduit made from durable and corrosion-resistant Stainless steel, valued for its robustness and adaptability in a wide array of industrial applications. Fabricated through seamless or welded processes, these tubes maintain structural integrity and withstand harsh environmental conditions, including corrosive fluids and high temperatures.

Stainless steel tubes exhibit versatility across industries such as construction, automotive manufacturing, and food processing. They serve pivotal roles in fluid and gas transportation, structural frameworks, and heat exchange systems. Yupeng Steel stands out as a leading manufacturer of precision-engineered Stainless steel tubes, ensuring top-notch quality and reliability. Their products are crafted to meet rigorous industry standards, delivering solutions that excel in durability and performance across global markets.

FAQ

Q: How are Stainless steel tubes used in water treatment plants?

A: They are used for conveying water, wastewater treatment systems, and desalination plants due to their corrosion resistance and ability to handle varying pH levels.

Q: What are the considerations for Stainless steel tube bending and forming?

A: Considerations include tube diameter, wall thickness, bending radius, and use of proper tools and lubricants to avoid deformation or cracking during forming processes.

Q: How are Stainless steel tubes used in chemical processing plants?

A: They are used for transporting corrosive chemicals, reactor vessels, and heat exchangers due to their resistance to acids, bases, and high temperatures.

Q: What are the re

Quirements for Stainless steel tubes in cryogenic applications?

A: Tubes must maintain ductility and toughness at low temperatures, making austenitic Stainless steel grades like 304L and 316L suitable for cryogenic storage and handling.

Reviews

Thaddeus

These stainless steel plates are a game-changer for our manufacturing process. They are easy to work with and maintain their structural integrity under high stress. Fantastic value for money.

Dashiell

I have used many different types of stainless steel plates, but these are by far the best. The material is top-notch, and they arrived in perfect condition. Will definitely buy again!

Latest Inquiries

To protect the privacy of our buyers, only public service email domains like Gmail, Yahoo, and MSN will be displayed. Additionally, only a limited portion of the inquiry content will be shown.

Scarlett***@gmail.comCanada

We have an urgent requirement for a large quantity of stainless steel plates and rolls. Please provi...

Amelia***@gmail.comUS

We are considering switching to a new supplier for our stainless steel plates and rolls. Could you s...

Related product categories

- 20mm stainless steel tube manufacturers

- 316 stainless steel square tube sizes

- 303 stainless steel tube manufacturers

- 316 stainless steel tube price

- 304 stainless steel rectangular tube manufacturers

- bending 316 stainless steel tube

- 304 stainless steel tube manufacturer

- brushed stainless steel round tube

- 304 stainless steel tube manufacturers

- half round stainless steel tube

- 304l stainless steel tube manufacturers

- mirror polished stainless steel tube

EN

EN FR

FR ES

ES PT

PT AR

AR DE

DE