1940 nickel alloy bars

A Nickel alloy is a high-performance material primarily composed of nickel and often combined with elements like chromium, iron, and molybdenum to enhance its properties. Known for its exceptional resistance to corrosion and oxidation, Nickel alloy maintains its structural integrity under extreme temperatures and harsh chemical environments, making it indispensable in many industrial applications.

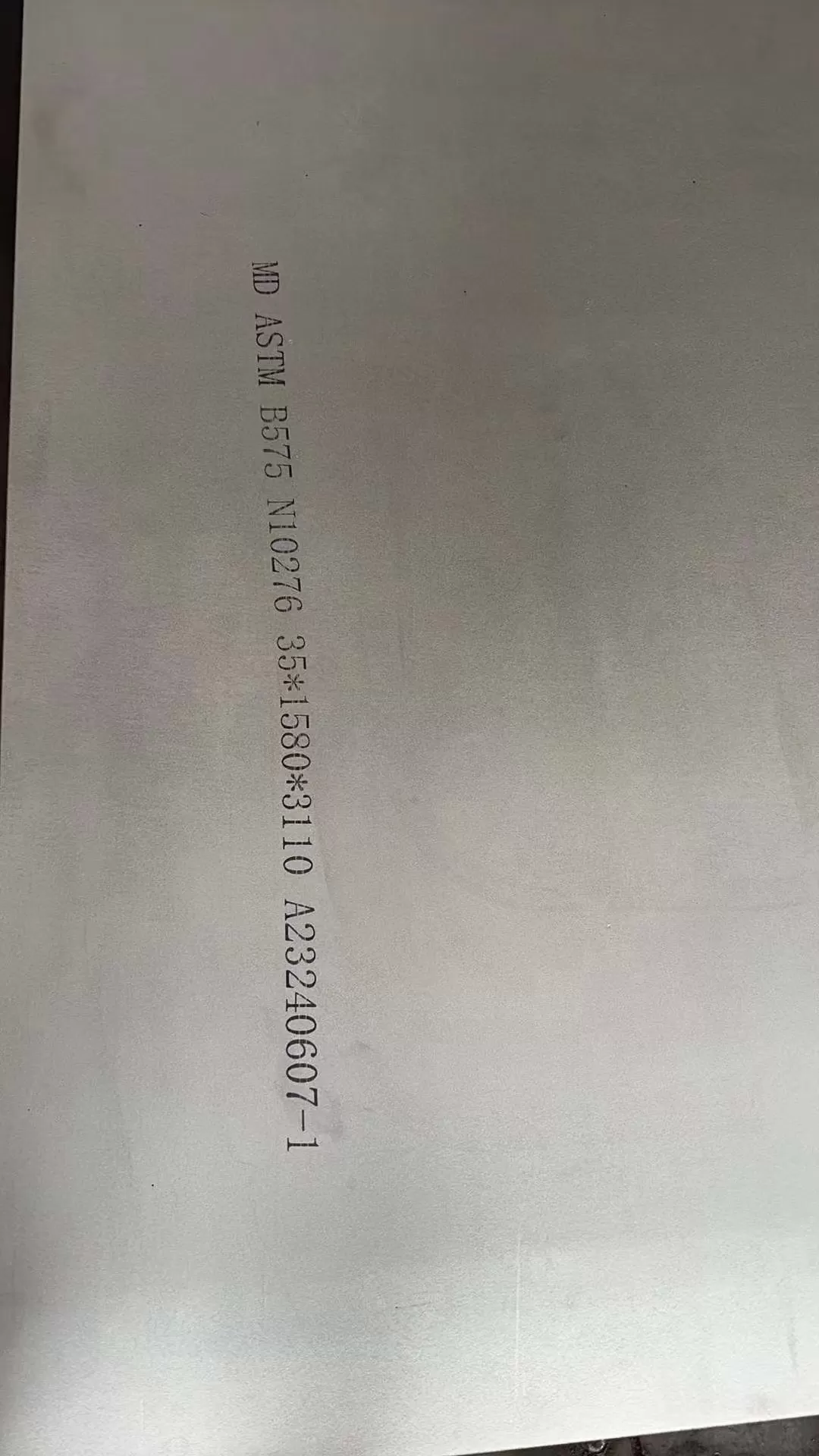

The benefits of Nickel alloy are numerous, including its excellent mechanical strength, durability, and resistance to thermal expansion. These properties make it ideal for use in demanding sectors such as aerospace, chemical processing, and power generation, where reliability and longevity are crucial. Yupeng Steel is a leading provider of high-quality Nickel alloy products, ensuring precision engineering and adherence to stringent quality standards to meet the diverse needs of global industries.

Yupeng 1940 nickel alloy bars

Nickel alloy is a specialized material composed predominantly of nickel, with additional alloying elements such as chromium, iron, and molybdenum. This combination gives Nickel alloy exceptional properties including high corrosion resistance, excellent mechanical strength, and remarkable heat resistance. These alloys are designed to withstand extreme temperatures, harsh chemical environments, and heavy mechanical stress, making them vital for critical applications across various industries.

Yupeng Steel is a renowned manufacturer of Nickel alloy products, known for their precision engineering and adherence to rigorous quality standards. They produce a wide range of Nickel alloy components tailored to meet diverse industrial requirements, ensuring reliability and performance in demanding environments. Yupeng Steel's commitment to innovation and excellence makes them a trusted partner for industries seeking high-quality Nickel alloy solutions worldwide.

FAQ

Q: What are the challenges of machining Nickel alloys?

A: Challenges include work hardening, poor chip control, and tool wear due to their high hardness and tendency to generate heat during machining.

Q: How are Nickel alloys tested for quality and performance?

A: Testing methods include mechanical testing (tensile, hardness), chemical analysis, non-destructive testing (ultrasonic, radiographic), and microstructural examination.

Q: What are the environmental considerations of using Nickel alloys?

A: Nickel alloys are recyclable and contribute to sustainability efforts in manufacturing, reducing environmental impact compared to some alternative materials.

Q: How are Nickel alloys used in the aerospace industry for lightweighting?

A: Nickel alloys are used to reduce weight in aircraft components without compromising strength, enhancing fuel efficiency and performance.

Reviews

Cassian

I am very impressed with the stainless steel plates I purchased. They have a beautiful finish and have maintained their appearance even in harsh conditions. Excellent product!

Isolde

The quality of these stainless steel plates exceeded my expectations. They are robust, resistant to rust, and have a high-grade finish. Perfect for both industrial and home projects.

Latest Inquiries

To protect the privacy of our buyers, only public service email domains like Gmail, Yahoo, and MSN will be displayed. Additionally, only a limited portion of the inquiry content will be shown.

Henry***@vitamaxprime.comAustria

I am looking for stainless steel plates and rolls with specific dimensions and grades for a large-sc...

Amelia***@gmail.comUS

We are considering switching to a new supplier for our stainless steel plates and rolls. Could you s...

Related product categories

- price for nickel alloy bar

- price of nickel alloy bar

- stainless & nickel alloy bar

- suppliers of nickel alloy bars

- washington alloy 1 16 rbcuzn-d bare nickel-silver copper

- nickel alloy plate

- nickel plated zinc alloy

- copper nickel alloy tube

- nickel alloy tube

- corrosion resistant nickel alloy plate

- heat resistant nickel alloy plate

- nickel 200 alloy plates

EN

EN FR

FR ES

ES PT

PT AR

AR DE

DE